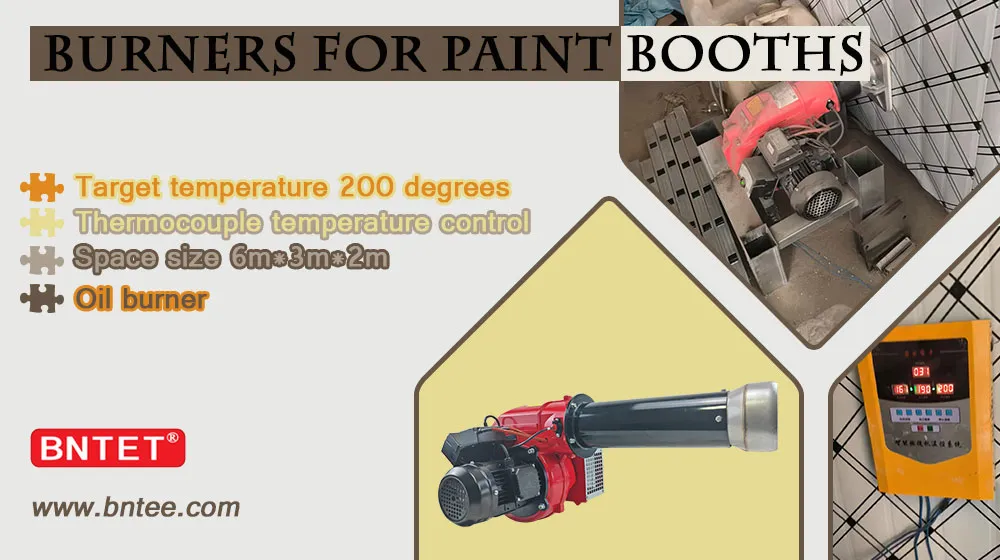

Burner for paint booths

2025-04-03 13:45:44

The customer main requirements are:

1. Heating to 200 degrees within 10 minutes

2. The temperature can be maintained at around 200 degrees without significant changes

3. Save raw material costs

4. Heating space size 6m*3m*2m

Our recommendations:

Power calculation (accurate version)

Key parameters:

●Space volume: 6×3×2=36m³

●Temperature rise requirement: 20℃→200℃ (ΔT=180℃)

●Heating time: 10 minutes (0.167 hours)

●Air density: 1.293kg/m³ (20℃)

●Air specific heat capacity: 1.005kJ/(kg·K)

●Thermal efficiency: calculated as 85% (typical value of diesel burner)

Calculation formula:

Q = (m×c×ΔT)/(η×t)

= (36×1.293×1.005×180)/(0.85×0.167)

≈ 58,200kJ/h ≈ 162kW

Recommended power: 180-200kW (considering 20% safety margin)

Here are our recommendations for buying a burner for baking varnish:

Burner Purchase Notes

When using a burner for heating in a paint spraying room (paint baking room), it is necessary to comprehensively consider the fuel type, heating efficiency, safety, operating costs and environmental protection requirements.

The core role of the burner

In a paint spraying room (paint baking room), the core function of the burner is to provide a stable and efficient heat source, which is mainly used in the following key links:

1. Accelerate paint curing (paint baking)

2. Control the temperature and humidity of the paint spraying environment

3. Improve work efficiency