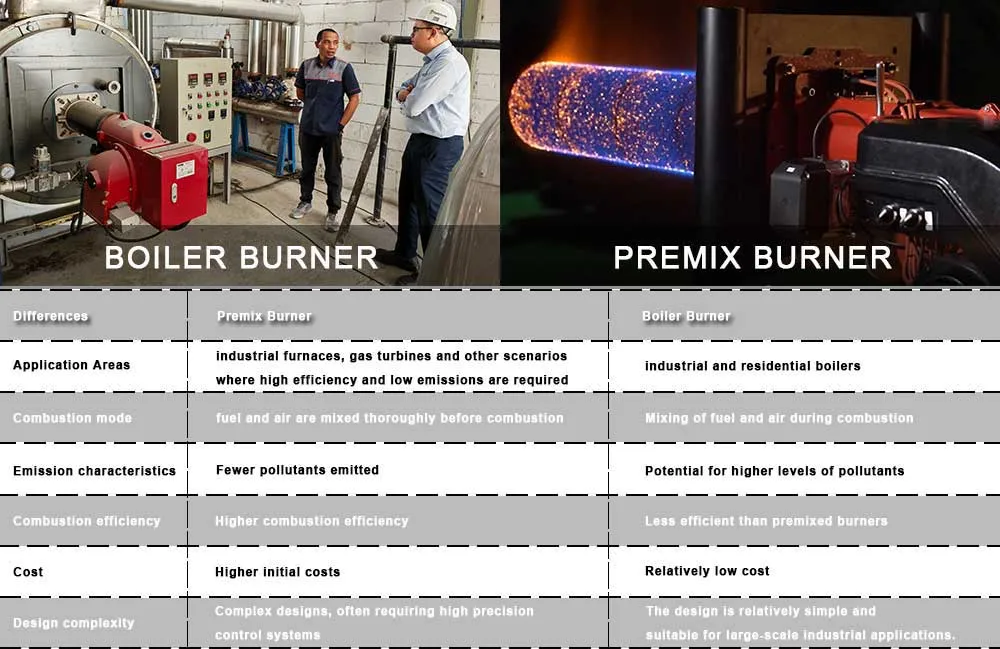

Differences between premix burners and boiler burners

2024-10-07 10:25:35

The differences between a premix burner and a boiler burner are mainly in design, application, combustion method and efficiency. The following are their specific differences:

1. Combustion mode

Premix burner: fuel and air are mixed thoroughly before combustion to ensure more complete combustion, usually used in applications requiring efficient combustion and low emissions.

Boiler burner: It can be either premix or diffusion type (common burner), and the degree of mixing of fuel and air may be different depending on the design requirements of the boiler.

2. Application Areas

Premix burners: Mostly used in industrial furnaces, gas turbines and other scenarios where high efficiency and low emissions are required.

Boiler burners: specially designed for boiler systems, suitable for applications such as heating, steam production, etc. Usually used in industrial and residential boilers.

3. Combustion efficiency

Premix burners: Higher combustion efficiency due to thorough mixing, which maximizes fuel utilization and reduces unburned emissions.

Boiler burners: Efficiency depends on the specific type and design, and certain boiler burners may have lower efficiencies, especially traditional diffusion burners.

4. Emission characteristics

Premix burners: emit fewer pollutants, meet stricter environmental standards and are suitable for applications with high emission requirements.

Boiler burners: Emission characteristics are dependent on burner design and fuel type, and some conventional boilers may produce higher levels of pollutants.

5. Design complexity

Premix burners: The design is more complex and usually requires a highly accurate control system to ensure the stability of the mixing ratio and combustion process.

Boiler burners: relatively simple design, especially the traditional diffusion burners, suitable for large-scale industrial applications.

6. Cost

Premix burners: Higher cost, but potential operating cost savings in long term operation due to high efficiency and low emissions.

Boiler burners: relatively low cost, suitable for projects with limited budgets.

To summarize

There are significant differences between premix burners and boiler burners in terms of combustion efficiency, application scenarios, and design complexity. Choosing the right type of burner requires a comprehensive evaluation based on specific application requirements, emission standards and economic considerations.