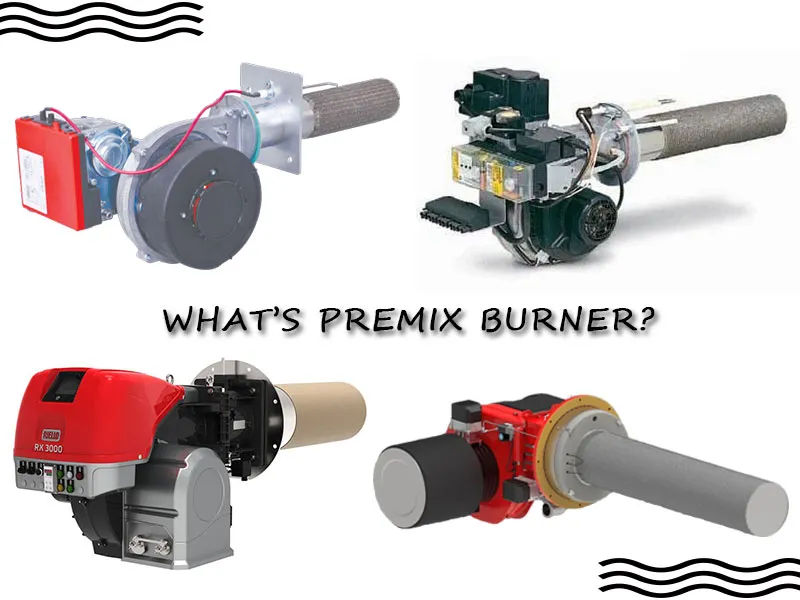

What is a premix burner

2024-10-11 14:07:30

A premix burner is a device that fully mixes fuel and air before combustion. Its main features and working principle are as follows:

Main features

⚙️Full mixing: Fuel (such as natural gas or oil) and air are fully mixed before entering the combustion chamber to ensure a uniform mixing ratio.

⚙️High combustion efficiency: Due to the mixing before combustion, premix burners can achieve more complete combustion, reduce the emission of unburned fuel, and improve combustion efficiency.

⚙️Low emissions: Premix burners can usually significantly reduce the emission of harmful gases, such as carbon monoxide and nitrogen oxides, and meet more stringent environmental standards.

⚙️Flame characteristics: The flames produced are usually more stable and the temperature distribution is more uniform, which is suitable for applications requiring high temperatures.

Working principle

⚙️Mixing process: Inside the burner, the fuel and air are fully mixed through a specific nozzle and mixing chamber to form a uniform mixed gas.

⚙️Ignition: The mixed gas is ignited under the action of the ignition device to form a flame.

⚙️Combustion process: The mixed gas burns in the combustion chamber, releasing heat, which is used to heat water, steam or other media. It is widely used in equipment such as industrial furnaces, boilers and gas turbines.

Main components

⚙️Fuel supply system

Fuel pipeline: used to deliver fuel (such as natural gas, diesel, etc.) to the burner.

Fuel valve: controls the fuel flow rate to ensure proper fuel supply.

⚙️Air supply system

Blower: provides the required air flow rate to ensure that the fuel and air are fully mixed.

Air pipeline: delivers air to the burner.

⚙️Mixing chamber

Mixer: fuel and air are fully mixed here to form a uniform combustible gas. The design of the mixer is crucial to combustion efficiency and stability.

⚙️Ignition system

Ignitor: such as spark plug or heating wire, used to ignite the mixed gas. The reliability of the ignition system directly affects the start-up performance of the burner.

⚙️ Combustion chamber

Burner housing: contains the mixed gas and provides combustion space, usually made of high temperature resistant materials.

Nozzle: controls the ejection of the mixed gas, affecting the combustion characteristics and flame shape.

⚙️Control system

Control valve: adjusts the flow rate of fuel and air to achieve automatic control.

Sensor: monitors temperature, pressure and flame status to ensure safe operation.

⚙️Safety device

Flame failure protection device: automatically cuts off the fuel supply when the flame goes out to prevent leakage.

Overpressure protection device: prevents excessive pressure in the combustion chamber to ensure safe operation.

⚙️Smoke exhaust system

Flue: discharges the exhaust gas generated by combustion, usually connected to the boiler or other equipment.

Smoke exhaust valve: controls the exhaust flow to ensure the normal operation of the system.

Application areas

Premix burners are widely used in:

?Industrial furnaces

?Boilers

?Gas turbines

?Heating systems

?Other equipment that requires efficient combustion

Summary

Premix burners have become important combustion equipment in the modern industrial field due to their high efficiency, low emissions and stable flame characteristics, and are suitable for a variety of high-demand applications.