Why do boiler burners backfire and how can I prevent it

2024-12-02 11:16:23

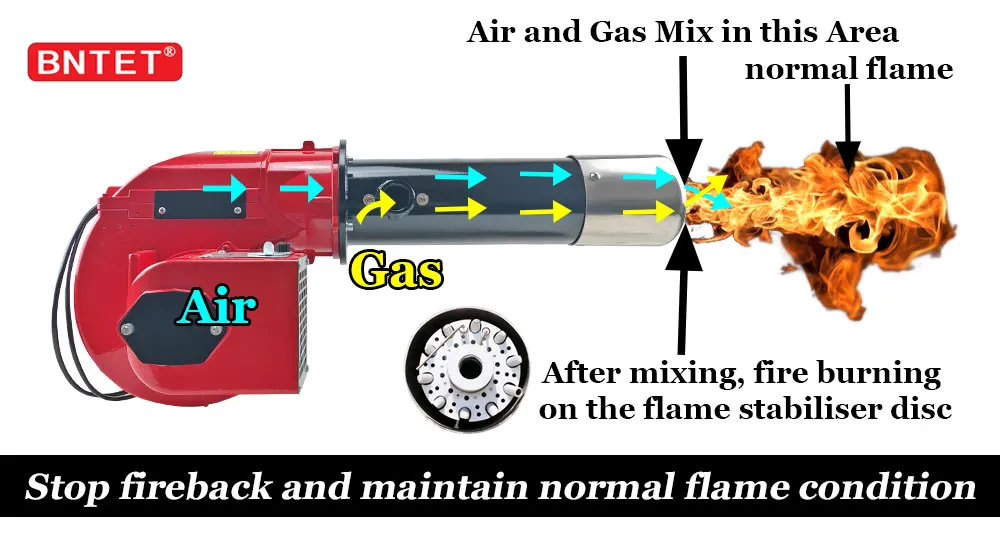

Boiler burner backfire refers to the combustion process flame or high temperature gas reverse back to the burner inside, which can lead to equipment damage or safety hazards, backfire serious burner will lead to direct scrap.

What's backfire

If the velocity of the unburnt combustible gas stream is too low, less than the flame propagation velocity, resulting in the flame will be flown inside the nozzle, known as backfire.

Causes of boiler burner backfiring

⚙️Uneven mixing of fuel: Uneven mixing of fuel and air leads to high local concentration, which is easy to trigger backfire.

⚙️Improper burner design: the structure of the burner is not reasonably designed, which may lead to unstable flame, resulting in backfire phenomenon.

⚙️Negative pressure condition: Negative pressure in the boiler system may lead to flame backflow to the burner.

⚙️Insufficient airflow velocity: The airflow velocity is too low to effectively push the flame towards the boiler, resulting in backfire.

⚙️Improper ignition: the flame fails to stabilise at the burner outlet during ignition, which may lead to flame backflow.

Measures to boiler burner backfiring

⚙️Optimise burner design: Choose the right type of burner and ensure that it is designed to effectively prevent boiler burner backfiring.

Cooling of the burner head to reduce the flame propagation velocity there.

⚙️Ensure good fuel mixing: Use a suitable mixing device to ensure that the fuel and air are well mixed to avoid excessive localised concentrations.

To ensure a uniform distribution of the velocity field of the gas mixture from the burner head into the fire path (or combustion chamber), the head can be made to shrink.

⚙️Install a tempering valve: Install a tempering valve between the burner and the boiler to prevent flame backflow.

⚙️Maintain proper airflow velocity: Ensure that the airflow velocity of the burner is within the design range to effectively push the flame towards the boiler.

Maximise the pressure of the gas mixture before it enters the fire escape from the nozzle and control the volume of gas or air by means of a regulating valve.

⚙️Regular maintenance and inspection: Check the operating conditions of the burner and boiler on a regular basis to ensure that the components are working properly and that potential problems are identified and dealt with in a timely manner.

⚙️Use of flame monitoring system: Install a flame monitoring system to monitor the flame status in real time, detect abnormalities and take measures in time.

Through the above measures, the backfire phenomenon of the boiler burner can be effectively reduced to ensure the safe and stable operation of the boiler.