Tubular Heat Exchanger

Tube heat exchanger is commonly used in chemical and alcohol production of a heat exchanger. Mainly by the shell, tube plate, heat exchanger tube, header, folding baffle and so on.

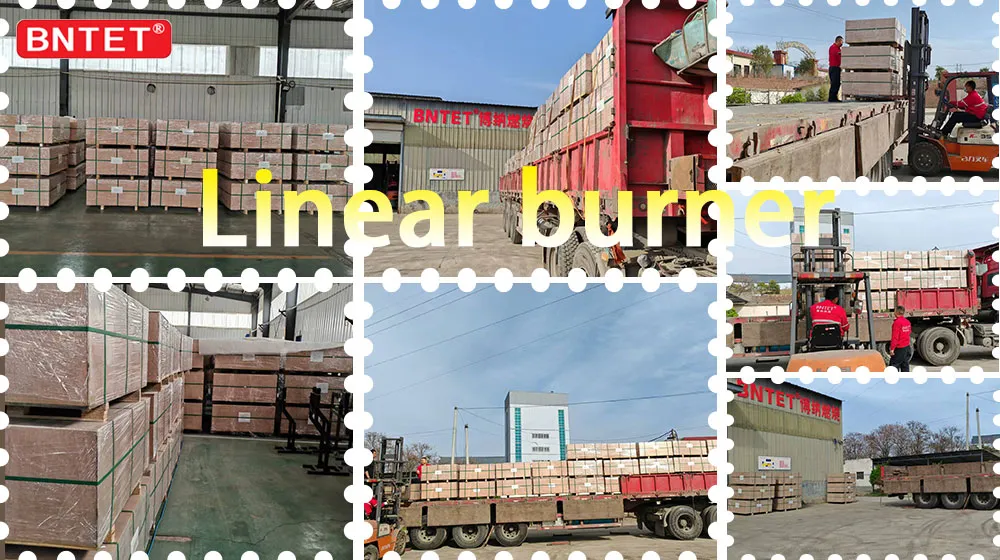

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

TUBULAR HEAT EXCHANGER DESCRIPTION

Tube heat exchanger is commonly used in chemical and alcohol production of a heat exchanger. Mainly by the shell, tube plate, heat exchanger tube, header, folding baffle and so on.

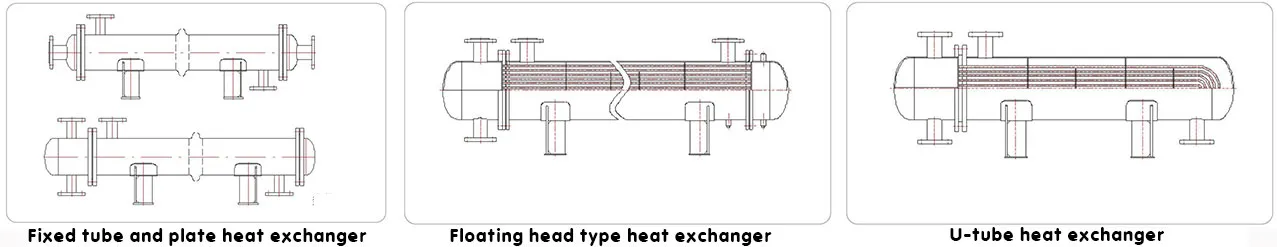

OUR COMPANY PRODUCES TUBE HEAT EXCHANGER:

?Fixed tube and plate heat exchanger

?Floating head type heat exchanger

?U-tube heat exchanger

TUBULAR HEAT EXCHANGER WORKING PRINCIPLE➡

Question 2-Product Parameter

DIMENSIONS AND WEIGHTS

?Diameter up to 6,00 mm

?Length up to 6 m

?Total weight up to 30 t

?Operating pressure up to 6.4Mpa

TUBULAR EXCHANGER PROCESS MEDIA

?Refrigerants (NH3, CO2)

?Process gases (O2, H2, He, CO2, etc.)

?Oils (lubricating oils, thermal oils, edible oils)

?Alcohols (C2H5OH)

?Water, process steam, sterile steam, vapours

?Air, exhaust gases and flue gases

?Hydrocarbons (CH4, C2H6, etc.)

TUBULAR EXCHANGER MATERIAL

?Structural steels

?Heat-resistant steels

?Fine-grained structural steels

?Chrome-nickel steels

Question 3-Product Display

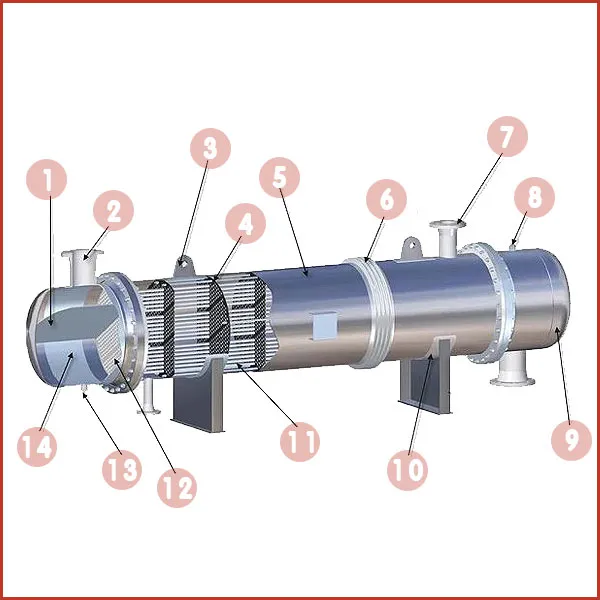

PRODUCT DETAILS

| 1.Baffle plate |

| 2.Tube side connection |

| 3.Lifting lug |

| 4.Baffle |

| 5.Shell |

| 6.Expansion joint |

| 7.Shell side connection |

| 8.Vent |

| 9.Rear channel |

| 10.Reinforcing pad |

| 11.Tube bundle |

| 12.Tubesheet |

| 13.Drain |

| 14.Front channel |

tubular-heat-exchanger-details01

tubular-heat-exchanger-details02

Question 4-Application

Question 5-FAQ

Q:What Components are Used in a Shell and Tube Heat Exchanger?

A:Shell/Tubes/Tube Sheets/Baffles/Rods and Spacers/Channels ect.

Q:Advantages of tubular heat exchangers

A:Low maintenance costs. High working pressure.

Q:What is the difference between plate heat exchanger and tubular heat exchanger?

A:The plate heat exchanger is ideal for low-duty oil cooking, barrage cooling, small district heating, etc. On the other hand, the shell and tube exchanger is suitable for mining machinery, swimming pool heating, hydraulic power packs, and the like.

Question 6-Our service

PACKAGE

Hot Tags: tube heat exchanger,heat exchanger,tubular heat exchanger

none

none